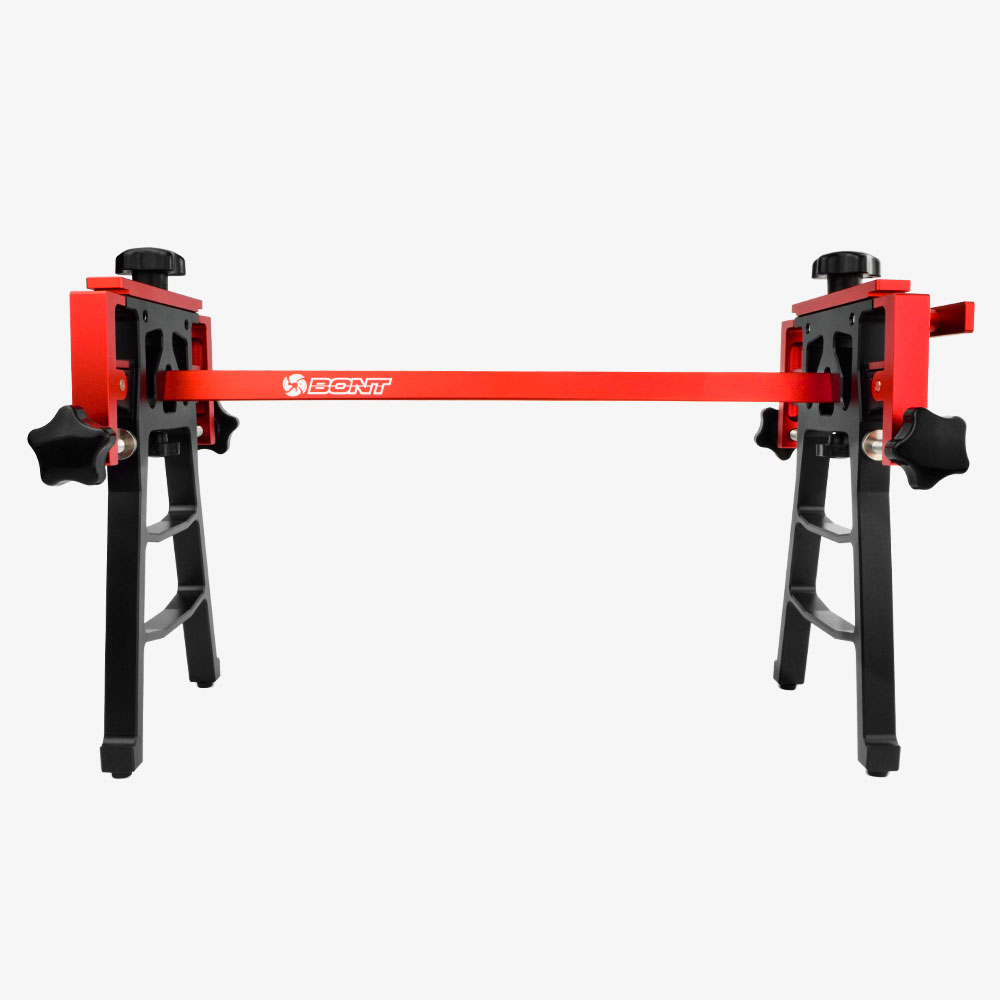

BONT Pro Sharpening Jig Designed by Gael Doucet-Gagnon

Original price was: $528.00.$399.00Current price is: $399.00.

The Bont precision short track jig was designed by Canadian short track speed skater Gael Doucet-Gagnon. You can read about his thought process of how he designed the jig

BONT Pro Sharpening Jig Designed by Gael Doucet-Gagnon

The Bont Pro Sharpening Jig by Gael Doucet-Gagnon. It was designed by Canadian short track speed skater Gael Doucet-Gagnon. You can read about his thought process of how he designed the jig.

Short Track: A sport of details

I’ve started skating when I was 6 years old, and ever since I’ve been fascinated by the sport of speed skating. On the surface it looks like a simple sport, where we skate as fast as we can going left on an oval ice track. Actually, it’s not as simple, it’s focussed on details. When the plan is to be the fastest skating the oval track, the task is quite complex. How do you become the best at the sport? By spending years practicing and perfecting your technic, working on strategies, and being at your best physical condition. As for equipment, the same principles apply. Boots fitted perfectly, blade’s that glide the ice and some protection. Again, it appears simple but not as easy to produce. Skating towards our full potential requires the equipment be optimized for our sport.

It’s not rocket science, but the complexity behind this simple idea, the way we chose to make it so perfect, and the passion involved behind this not quite simple jig is what makes it so special. Just like the sport of speed skating.

My experience as 20 years old speedskater and my constant interest in the complexity of the equipment have been an ongoing inspiration for wanting to contribute in bettering its apparatus.

Knowing my ongoing passion for that, Mr. Marc Pelletier the owner of Xact Performance and Canadian distributer for Bont Canada posted in Quebec offered me the opportunity to realize my dream. Bont wanted to produce a new speed skating sharpening jig, and he asked me if I would be interested in designing one for them. Gladly I accepted knowing that my studies in civil engineering would assist me in achieving the goal.

Thought process

In designing a new sharpening jig, I made use of a 3D visualization plan in wanting to represent the machining specifications and demonstrate it’s potential. Having learned how to use CAD (computer-aided design) at school, I used the software AutoCAD to get the job done. While creating the product, my objectives were the same as in civil engineering: optimizing quality with production efficiency.

- My first goal was to be certain that the jig could fit every brand of blades on the market, no matter the degree of their wear and tear. Some removable items were designed and specifications of the dimensions of the jig were given to assure every existing blade on the market worldwide would get its perfect fit. Also, I needed to make certain the least amount of tension was to be laid on the blades. The reason for that is to not affect their bending while keeping a good grip to them when sharpening.

- My second goal was to minimize the total weight and promote its long-lasting durability. I wanted the jig to be lightweight and to be easily packed when traveling to train and to competitions. As we do in civil engineering, I chose to play with the shape of the product. Where it was possible in doing so, I optimized the design in order to diminish its weight. I made certain to keep more material on the more accident-prone areas. Most likely to be deformed in case of misfortune

- My third goal was to design a jig that was easy to produce for making the jig affordable for everyone. Again, I adapted the forms making them easy to engineer so we could diminish the selling price of the product. In doing so, we would also decrease the potential risk of manufacturing defects.

-

Finally, I wanted every piece of the assembly to be easily accessible. In order to standardize the product, a norm was found for each screw or piece used for assembling this jig.

Bont short track speed skating sharpening jig

I came up with a basic design for the precision sharpening jig but had different ideas concerning some specificities that could be included or not in to the design. Not knowing which one Bont would prefer, five slightly different options of 2D plans were given based on 3D designs. The model chosen was a unique design, using a 90-degree aluminum bracket that could be used to adjust the height of the blade sitting on the jig. As for the design, the prototype was successfully produced. More guidance and specifications were given to the machinist, so they could truly understand the intent of the requested changes. Initially intended for the Canadian market, from there on the production began.

As you know a speed skating precision sharpening jig does a quite simple job. In order to get a really sharp edge, like any other jig, the Bont Pro jig holds our blades at 90 degrees while sharpening… It’s not rocket science, but the complexity behind this simple idea, the way we chose to make it so perfect, and the passion involved behind this not quite simple jig is what makes it so special. Just like short track speed skating.

Author

Gaël Doucet-Gagnon

| Cup Height | 25mm (0), 28mm (+3), 29mm (+4), 32mm (+7) |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.