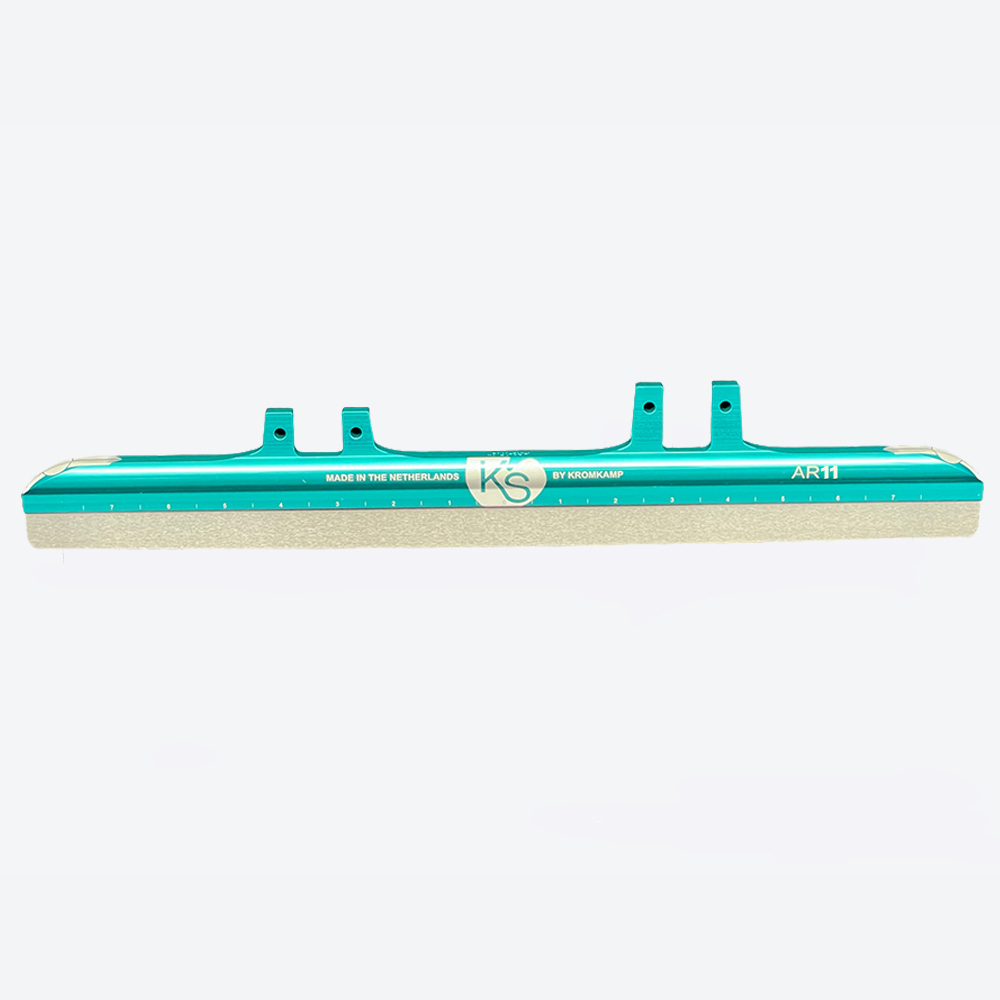

KROMKAMP AR11 ST Blades

Price range: $925.00 through $975.00

Professional tube for the medium weight (up to 155lbs) top skater speed skater who requires stiffness in the blade with a well steering top tube

KROMKAMP AR11 ST Blades

The KROMKAMP AR11 ST Blades are made with professional tube for the medium weight (up to 155lbs) top skater speed skater who requires stiffness in the blade with a well steering top tube.

Specifications of the AR11 ST Blades:

- 7000 Series Aluminum Skate Tube

- Stiff under the tube, stiff on top of the tube

- Lightweight aluminium cups from the 7000 series

- The Kromkamp AR11 blades come with Bi metal or PM steel, Bi-Metal or PM hand selected steel, Bi-Metal or PM hand selected steel extreme fine grinded polish

- Prebend 25 m radius

- Rocker 9 m radius

- Surface Grinding Machine, precision grinded steel

- Available sizes 17″-17.5″-18″

- Equivalent blades : EVO Argon, M WAVE Firm FT, EHS ACS

PLEASE INDICATE YOUR CUP SIZE IN THE COMMENT BOX

FROM : -1(24mm) to +10(35mm)

About PM Steel

Powder metallurgy (PM) steel, often referred to as powder metal steel, is a material made through a specialized manufacturing process known as powder metallurgy. This process involves the following key steps below:

- Powder Production: To produce high-quality steel powders, it has to go through various methods such as atomization, chemical precipitation, or mechanical comminution. After that, these powders are typically very fine, with particle sizes ranging from micrometers to several hundred micrometers.

- Powder Blending: To achieve specific material properties, the steel powders are carefully and thoughfully blended with other elements and alloys. Although, this can include adding elements like chromium, molybdenum, nickel, or others to enhance strength, corrosion resistance, or other characteristics.

- Compaction: The blended powders are compacted under high pressure into a die. Therefore this pressure, which can be several tons per square inch, compacts the powder particles into a solid mass known as a green compact.

- Sintering: The green compact is heated in a controlled atmosphere (often in a furnace) to a temperature below the melting point of the steel. During sintering, the powder particles bond together through diffusion, basically resulting in a fully dense, solid steel part.

The powder metallurgy process offers several advantages over traditional methods of steel production, including:

- Material Efficiency: Minimal material waste compared to machining from solid billets.

- Complex Geometries: Parts with intricate shapes and internal features which can be easily produced.

- Customization: Easily adjustable alloy compositions and material properties.

- Cost-Effectiveness: Can be more cost-effective for producing small to medium-sized batches of parts.

Therefore, powder metallurgy steels find applications across various industries, including automotive, aerospace, medical devices, and consumer electronics. Eventually, they use them for components where high strength, wear resistance, and dimensional accuracy are critical.

At last, examples of powder metallurgy steels include stainless steels, tool steels, and high-speed steels, each tailored to specific performance requirements through the powder metallurgy process.

PLEASE INDICATE YOUR CUP SIZE IN THE COMMENT BOX

FROM : -1(24mm) to +10(35mm)

Here is a guide to help you select the right blade:

The blade name includes the skater type and the tube radius type

Skater type

- C : Children skates, flex aluminum

- L : Lightweight, flex aluminum

- A : Average, standard flex

- AS : Average stiff, flex tube with stiffer upper tube

- S : Stiff, stiff tube with stiff upper tube

Bottom of the tube radius type:

- R8 : Tube designed for children.

- R3 : Tube deisgned to be flex for lightweight skaters

- R11 : Tube designed to be stiffer for more agressive/heavier skaters

Blade preparation : We do a ST-9 progressive rocker on them (see numbers here) as well as the matching bend

Know more about Kromkamp here

See other models here

| Lenght | 17", 17.5", 18" |

|---|---|

| Kromkamp Runner Steel | PM Hand Selected Steel |

| Blade preparation | No, Yes |

You must be logged in to post a review.

Reviews

There are no reviews yet.